Customer: ALLMATIC-Jakob Spannsysteme GmbH

Automated Loading of a Machine Tool

More and more manufacturing companies are facing the challenge of making their production processes more efficient while also dealing with an increasing shortage of skilled workers. Standardized processes that were previously carried out manually are quickly reaching their personnel and economic limits.

ALLMATIC-Jakob Spannsysteme GmbH has taken on this challenge – and, with a well-designed automation solution, has not only increased machine uptime but also paved the way for a flexible, future-proof production environment.

Rising Cycle Times and Skilled Labor Shortages Call for Smarter Solutions

ALLMATIC-Jakob Spannsysteme GmbH faced a situation that many manufacturing companies are currently experiencing: finding skilled operators for machine tending was becoming increasingly difficult – especially for second and third shifts.

Workpieces had to be manually loaded into the machine tool, clamped, machined, and then unloaded. This repetitive work tied up qualified personnel with simple, recurring tasks. At the same time, demand was growing for a flexible production process that could operate reliably outside of regular working hours – independent of staff availability.

Automated Machine Loading Around the Clock

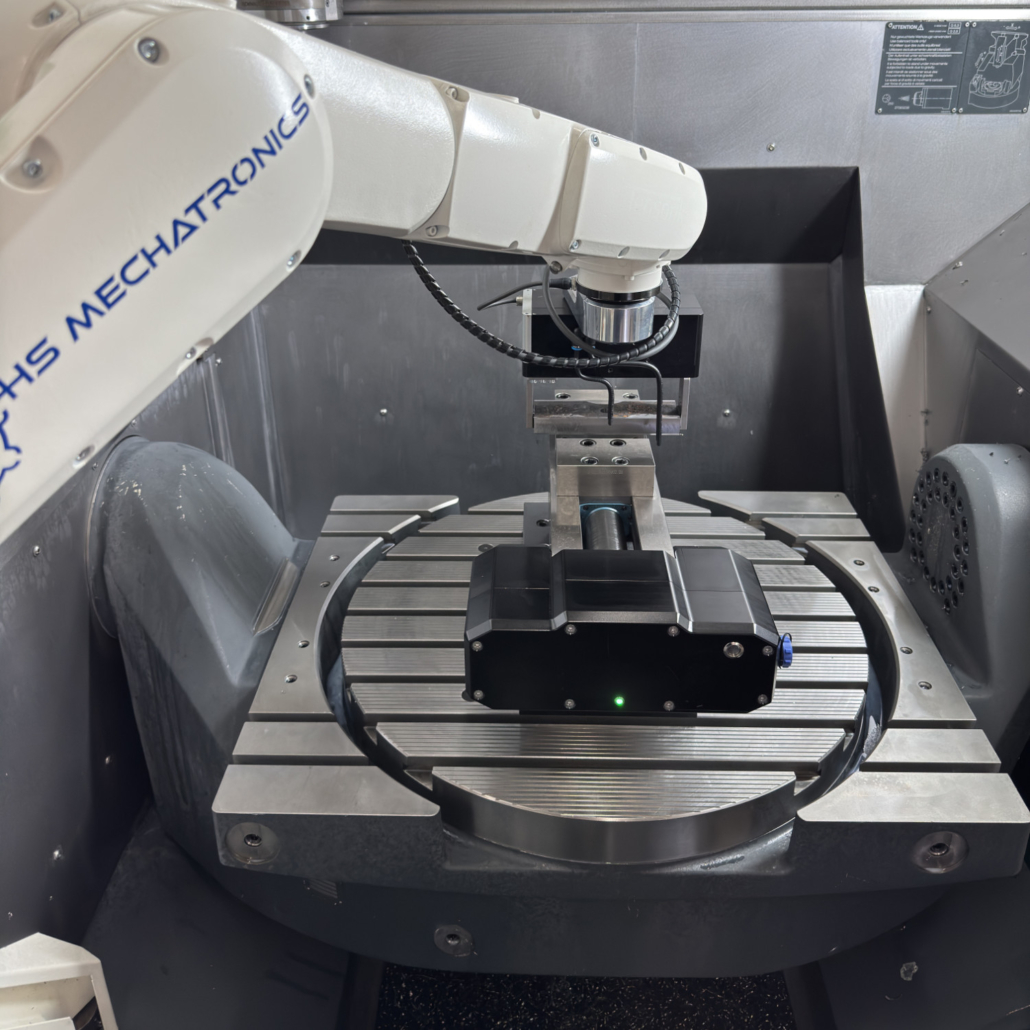

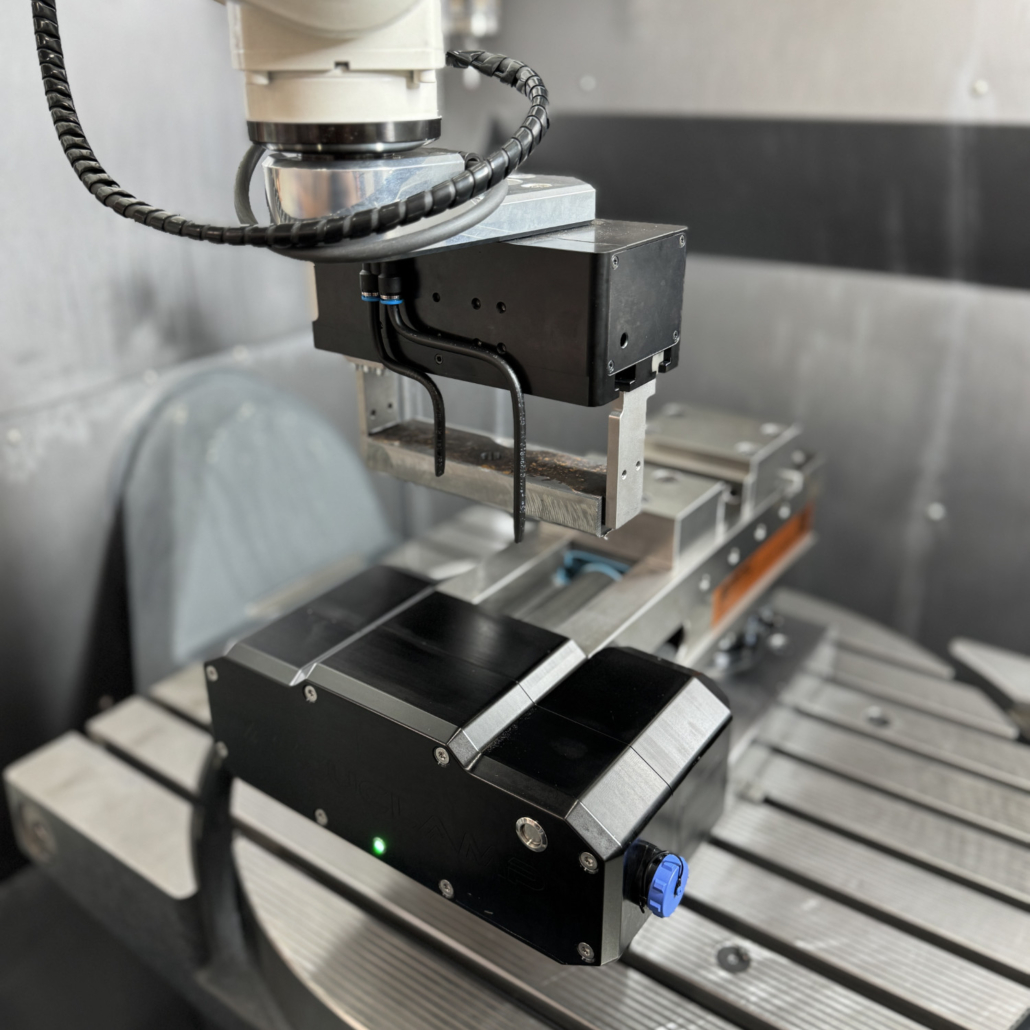

To increase machine utilization and address the shortage of skilled labor, a fully automated machine loading solution was implemented. At the core of the new system is the interaction between a robotic cell with an integrated workpiece storage unit, the machine tool, and an automated machine vise built into the machine. This automated clamping device – marketed under the name AccuClamp – was previously developed for ALLMATIC-Jakob Spannsysteme GmbH and enables automated, wireless clamping operations inside the machine tool.

An overview of the process:

- The robot retrieves a raw part from the storage unit and loads it into the machine.

- The vise automatically clamps the part.

- The machine enclosure door closes and the milling process begins.

- Once machining is complete, the finished part is removed and placed in the designated area.

- The cycle repeats until all workpieces have been processed.